- Home

- About Us

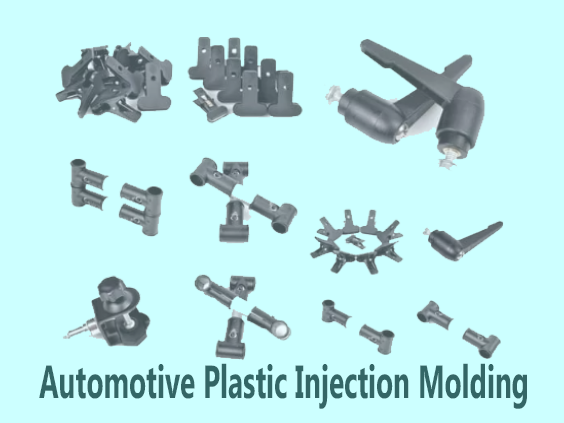

- Products

- Injection Molding Machine

- Servo Type Injection Molding Machine

- Ram Type Injection Molding Machine

- Electric Molding Machine

- PVC Injection Molding Machine

- Pet Injection Molding Machines

- Thin Wall Injection Molding Machine

- Multicolor Injection Molding Machine

- Standard Injection Molding Machine

- High Speed Injection Molding Machine

- Two platen Injection molding Machine

- Hybrid Injection Molding Machine

- Rotary Injection Molding Machine

- Blow Molding Machine

- Injection Molding Machine

- Applications

- Event

- Enquiry

- Careers

- Contact Us